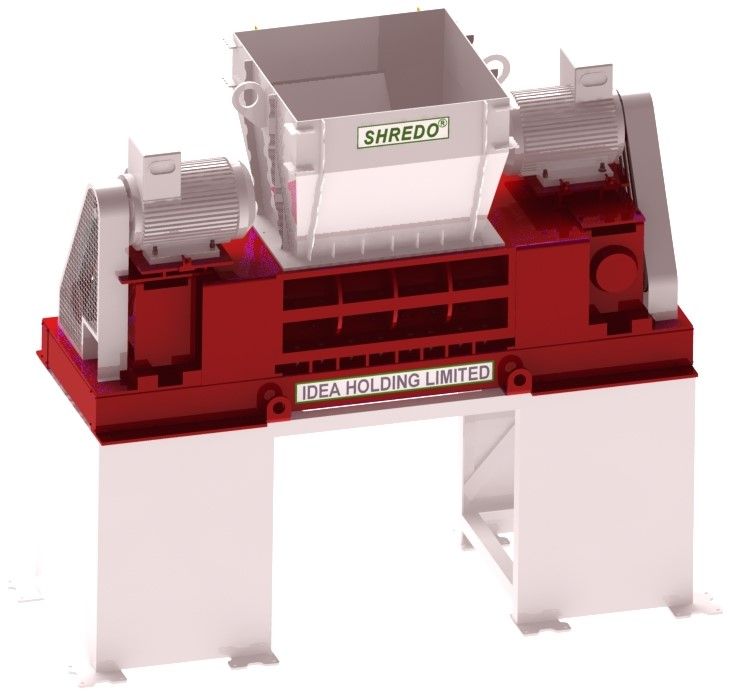

Municipal Solid Waste Twin Shaft Shredder

Municipal Solid Waste Twin Shaft Shredder Specification

- Application

- Municipal, Industrial, and Commercial Waste Shredding

- Blade Diameter

- 250 mm

- Blade Material

- High-strength Alloy Steel

- Cutting Type

- Shearing/Fragmentation

- Handle Type

- N/A (Industrial Machinery)

- Cutting Thickness

- Up to 25 mm

- Base Material

- Mild Steel Frame

- Pack Size

- Single Unit

- Thickness

- Panel thickness: 6 mm

- Features

- Low noise operation, high throughput, robust construction

- Type

- Twin Shaft Shredder

- Use

- Municipal Solid Waste Processing

- Sheet Capacity

- Up to 200 kg/hr

- Cutter Type

- Twin Rotary Cutters

- Cut Size

- Variable, adjustable as per requirement

- Start

- Automatic and manual options

- Auto-Stop

- Yes

- Motor Type

- Heavy Duty Induction Motor

- Bin Capacity

- 500 liters

- Noise Level

- Below 80 dB

- Basket Type

- Integrated Steel Bin

- Safety System

- Emergency stop button, overload protection

- Dimension (L*W*H)

- 2000 x 1200 x 1800 mm

- Weight

- Approx. 1500 kg

- Cutting Capacity

- Up to 200 kg/hr

- Power(W)

- 7500 W

- Voltage

- 415 V, 3 phase

About Municipal Solid Waste Twin Shaft Shredder

A municipal solid waste (MSW) twin shaft shredder is an industrial machine specifically designed for the efficient shredding of various types of municipal waste, including household garbage, commercial waste, and recyclable materials. This type of shredder uses two parallel shafts, each fitted with sharp, rotating blades, to break down waste into smaller, manageable pieces.

Key Features:

- Twin Shaft Design: The dual shafts provide powerful shredding capabilities, ensuring consistent and thorough processing of diverse waste materials.

- High Capacity: Designed to handle large volumes of waste, making it ideal for municipal waste facilities and recycling centers.

- Versatile Processing: Capable of shredding various materials, including plastics, paper, metals, organic waste, and more, enhancing recycling efficiency.

- Robust Construction: Built with heavy-duty materials to withstand the rigors of continuous operation and the impact of tough waste materials.

- Low Noise and Vibration: Engineered for quieter operation, reducing noise pollution in the surrounding environment.

- Safety Features: Equipped with safety mechanisms such as overload protection, emergency stops, and safety guards to ensure safe operation for personnel.

- Easy Maintenance: Designed for straightforward maintenance and access to components, minimizing downtime and maintenance costs.

Applications:

- Municipal Waste Management: Essential for shredding waste collected from households and businesses, making it easier to transport and process.

- Recycling Facilities: Helps in preparing materials for further recycling processes by reducing their size.

- Landfill Reduction: Shredding waste can significantly reduce its volume, leading to more efficient landfill usage.

- Organic Waste Processing: Effective for shredding organic materials, which can then be converted into compost or biogas.

In summary, a municipal solid waste twin shaft shredder is a vital component in modern waste management systems, enabling efficient processing and recycling of diverse waste materials, ultimately contributing to environmental sustainability and resource recovery.

4o mini

Advanced Dual Shaft Drive System

Our shredder utilizes a synchronized dual shaft drive with a planetary gear box, ensuring efficient shearing and fragmentation of a wide range of municipal solid waste materials. The robust drive mechanism maximizes throughput and longevity, even when processing tough materials like plastics and textiles.

User-Friendly PLC Touchscreen Control

Take command of operations with the PLC-controlled interface and integrated touchscreen. Automatic and manual start options, real-time parameter adjustment, and safety interlocks make waste management intuitive and safe for operators.

Optimized for Maintenance and Safety

Designed with maintenance in mind, the shredder offers easy access points for cleaning and servicing. Full body enclosure, overload protection, automatic grease lubrication, and an emergency stop button ensure operator safety and equipment durability.

FAQ's of Municipal Solid Waste Twin Shaft Shredder:

Q: How do I operate the Twin Shaft Shredder for municipal solid waste processing?

A: Operation is simple via the PLC touchscreen interface. You can start or stop the shredder automatically or manually, adjust shredding parameters as needed, and monitor system status in real time. Built-in safety features like emergency stop ensure secure handling.Q: What types of waste materials can this shredder process?

A: This shredder is compatible with a broad range of municipal solid waste, including organic matter, plastics, rubber, textiles, and mixed MSW. Its robust construction and adjustable settings make it suitable for diverse waste streams.Q: When is servicing or maintenance required, and how accessible are those components?

A: Routine maintenance should be performed based on usage levels, with recommended checks for blade wear, lubrication, and cleaning. The shredder features easy-access panels for straightforward cleaning, servicing, and blade replacement, reducing downtime significantly.Q: Where can the shredder be installed, and what support is available?

A: The shredder is designed for installation in municipal, industrial, or commercial facilities. On-site support for installation is available, ensuring seamless setup and integration into your existing waste management system.Q: What is the cutting capacity and how is the cut size managed?

A: The shredder can handle up to 200 kg/hour, with an adjustable cut size to accommodate various waste processing requirements. The twin rotary cutters made of high-strength alloy steel provide reliable shearing, capable of handling materials up to 25 mm thick.Q: How does the shredder benefit waste processing operations?

A: By delivering high throughput, reliable performance, and low-noise operation (below 80 dB), the shredder increases waste processing efficiency, reduces manual handling, and integrates easily with conveyor systems for automated material discharge.Q: What safety features are included with this shredder?

A: Safety is ensured through a full body enclosure, emergency stop button, overload protection, automatic lubrication, and noise-reducing design. These features help protect operators and prolong equipment life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free